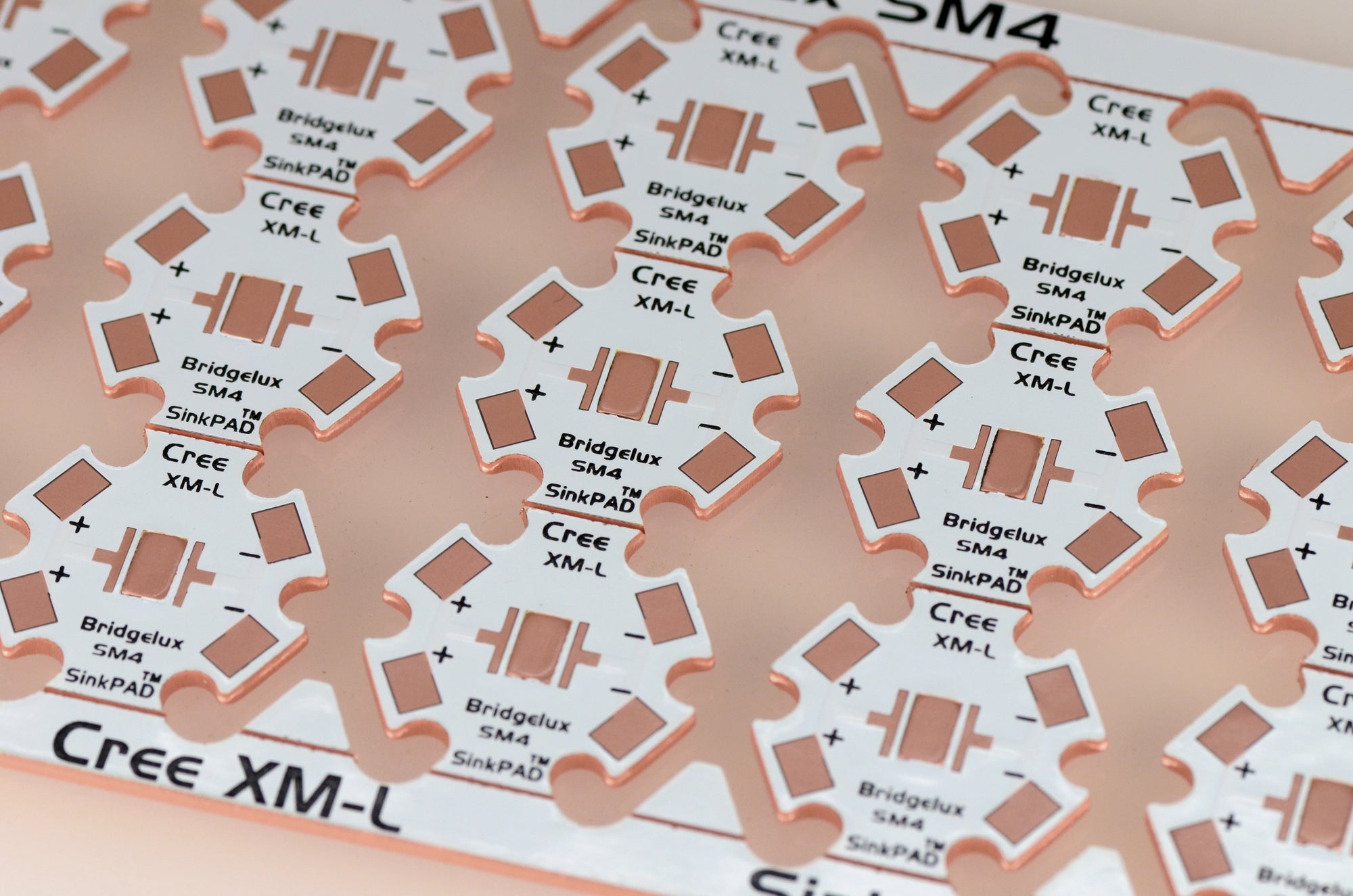

Copper 20mm MCPCB

{"name":"LED","position":1,"values":["XML","XPG\/NC219"]}

SinkPAD blows away "standard" MCPCBs...

I'm absolutely astonished at the increase in performance these boards provide. If you want to upgrade one thing in your light, this is it. Eventually every serious flashlight manufacturer will spec a SinkPAD MCPCB. Until that time, you can either buy an Alpha light or just the MCPCB.

Technology:

SinkPAD uses a proprietary manufacturing process to allow mounting the LED directly to the copper base material. There is NO intermediate dielectric layer like on a "standard" MCPCB. This means the LED runs cooler and brighter. A lot brighter. The most ambitious custom builders have long known that this "direct solder" method yeilds massive performance results. However, it's exceedingly difficult to accomplish. The SinkPAD "Direct Thermal Path" changes the game. This MCPCB isn't "quite" as good as that (because of the board thickness) but it's much much better than any other MCPCB.

I've switched over 100% of Alpha & Delta production to SinkPAD bases. As far as I know, I was the first manufacturer to adopt this technology when it first launched.

DTP was pioneered by individual makers & modders working on the kitchen table at home. Industry finally took notice and SinkPad was the first to bring a commercial product to market. I'd been following the maker/modder developments and immediately jumped at the opportunity to use SinkPad when they became available.

Today, several companies are manufacturing DTP boards and large flashlight companies have also picked up on the trend. It's the only way to mount and LED if you are running "modern" amounts of power through it. Budget brands don't use this kind of thing because it's expensive, and their lights suffer because of it. Don't be fooled by a "high output" light that doesn't use DTP boards...they won't deliver.

-

Industry size (diameter)20mm

-

thickness1.75mm

-

materialC101 oxygen free copper

-

where it's made