Task Master Mini (High CRI)

The Task Master Mini is an High CRI (90+) task light with a massively strong magnetic base. The base & bulb socket are 3D printed in-house.

I personally prefer the Mini over the original Task Master. Both lights are capable of the same surface illumination depending on focus and working distance. However, The Mini's lightweight head offers virtually unlimited positioning options compared to the heavier head on the Task Master.

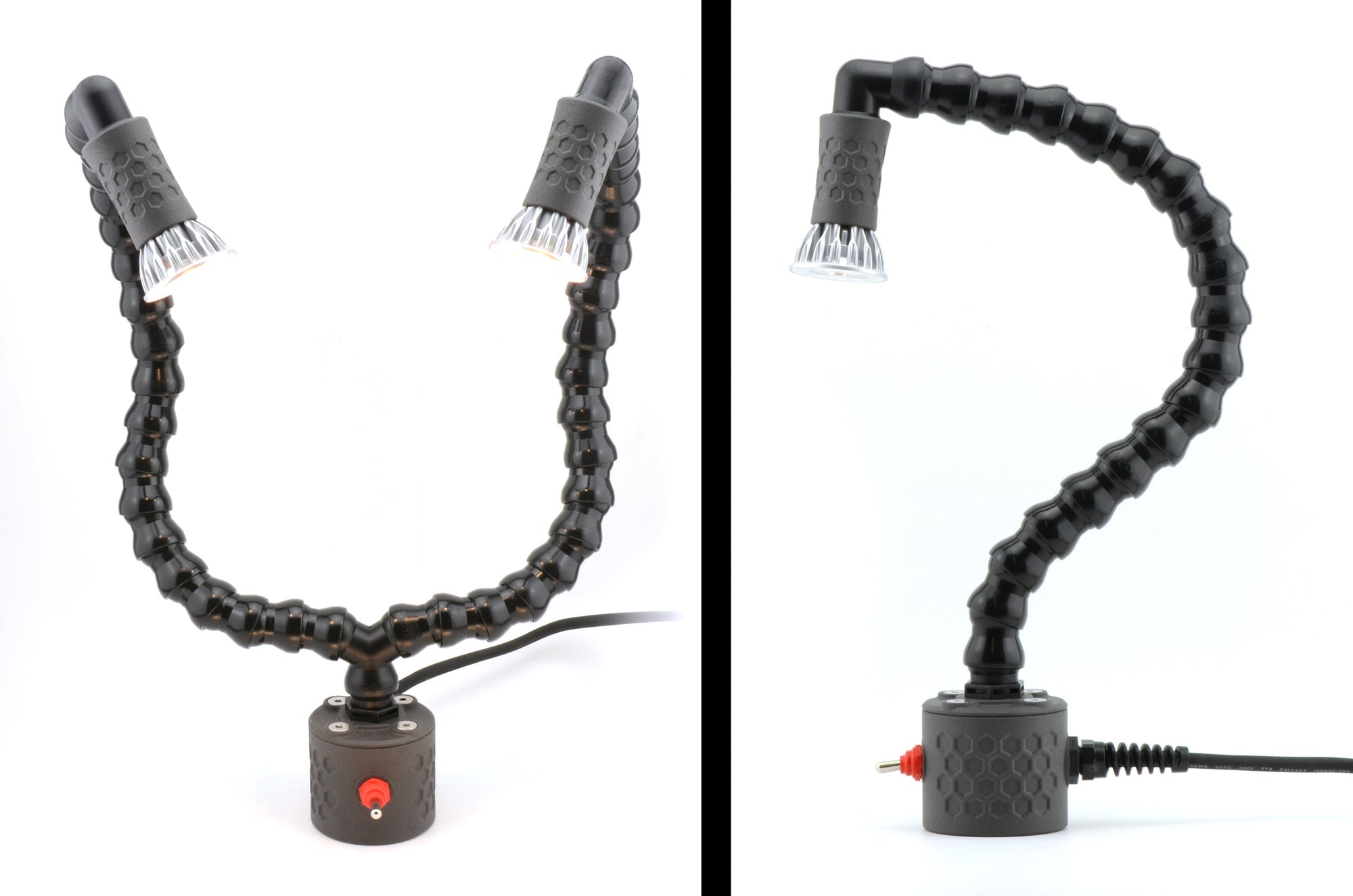

Task Master Mini (Single Head)

Task Master Mini Dual (Dual Head)

{"name":"Version","position":1,"values":["Mini","Mini Dual"]}

I wanted a great LED task light and couldn't fine one, so the obvious choice was to make it. I never know if I'm a snowflake that can never be satisfied, or if commercial task lighting just sucks. Based on the fact that I can't keep these in stock, I'm starting to suspect I'm not alone.

The Mini has a much smaller, lighter weight head to give you more flexibility in mounting. You can fully extend the head away from the base without it drooping. The coolest thing about this SORAA Brilliant bulb is you can magnetically attach modifiers that change the beam angle (included with each light).

This High CRI (90+) bulb is ONLY available in 3000K, which reduces glare and eye strain. I started out thinking 5000K was the right CCT for task lighting. I was wrong. I've converted all my personal task lights to 3000K. More details below.

The base features a massive cup magnet (with non-marking rubber boot) and an industrial toggle switch with a waterproof boot. The power cords are custom made for this application and sealed with a German-Made strain relief fitting. As usual, industrial grade and no expense spared.

Task lights have a magnetic base! They are not self-standing, so you'll need to attach it to something steel.

Introducing: the Task Master If you work up close, you already know that task lighting is incredibly important. It helps you work more quickly, more accurately, and with less fatigue. A task light has been on my "to do" list since 2013. I know, about time, but my to-do list is pretty long. The stars finally aligned and gave me everything I needed to make a boss task light for myself, and now I want to share it with you. I finally got an industrial 3D printer and it's a perfect tool for this job.

The main reason I never got around to making a task light was the disproportionate effort and mind boggling expense of machining it out of metal. Machined parts would make the retail price astronomical. Even if you'd pay the price, my CNC machines are running production all the time and there is rarely a moment to squeeze in something like this...something that takes days to set up and run the multiple parts required.

The more I print, the more I think 3D printing is really the future. Printing allows me to use design geometries that are impossible to machine. It also lets me make revisions on the fly since I'm just printing the parts I need on demand. With CNC it's more efficient to run larger batches of parts that need to be sold or scrapped if there are design changes. I'm constantly tweaking my printed parts. Most of those changes are to ease assembly and part processing, but that makes my life a lot easier (happier) and you get the same great performance.

- Splash resistance: The light should be splash resistant, but it's not waterproof or submersible. The bulb itself has no environmental sealing, and the base cap o-ring is only meant to keep liquids from seeping in from the gap. I opted for a sealed switch boot and cord grip to keep out common sources of contamination: sweaty, wet, or oily hands and various shop fluids that might drip down the cord and enter the base of the light.

- The Magnet: no, not a typo. It hold's 236 lbs. The magnet is covered with a rubber boot to prevent scratching and liquid ingress. To remove the task light from a magnetic surface you MUST rock the base sideways. There is no physical way to just pull it directly off of a surface.

- Loc-Line: if you bend the moving segments too far they can disconnect. If you've ever used loc-line you already know this. Be mindful not to bend the segments beyond their intended range, and also use two hands when positioning the light.

- Positioning: The Task Master Mini has a very lightweight head and offers virtually unlimited positining options compared to the heavier head on the Task Master.

- 90 Degree Head: This is a functional configuration even though it looks goofy. You can remove the 90 degree segment and reassemble the light if you wish.

- Heat: the bulb gets quite hot, but has plenty of cooling. The bulb shroud is designed as a handle, heat shield, and also cradles the base of the bulb to eliminate strain on the fragile bulb-to-socket connection.

-

voltage110V US ONLY

-

magnet2" neodymium cup magnet with rubber boot (236 lbs holding force)

-

cord length6 feet

-

bulbSORAA Brilliant 9050 High CRI (110V GU10 base)

-

output3000K (warm) @ 600 lumens (90+ CRI)

-

neck3/4 Loc-Line